We have partnered with Blue Red Gold to develop a precision automated solution for harvesting saffron. Today, picking, sorting and quality control of flowers and saffron stigmas are highly labour intensive. With the help of computer vision and robotics we reduce the need for these time consuming and cost ineffective tasks and enable effective year round harvesting of saffron.

We are working towards making the whole R&D factory in Strängnäs automatic.

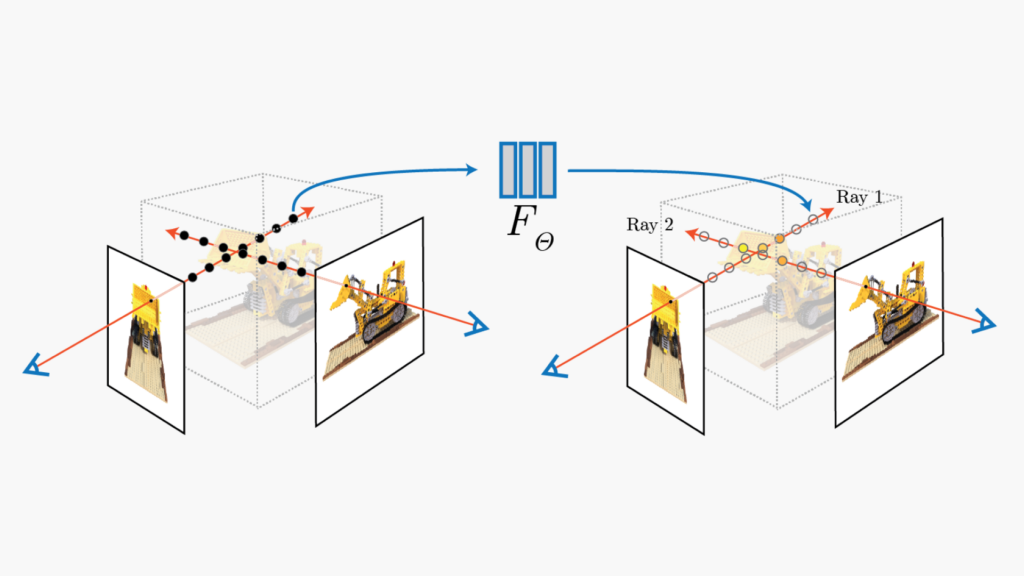

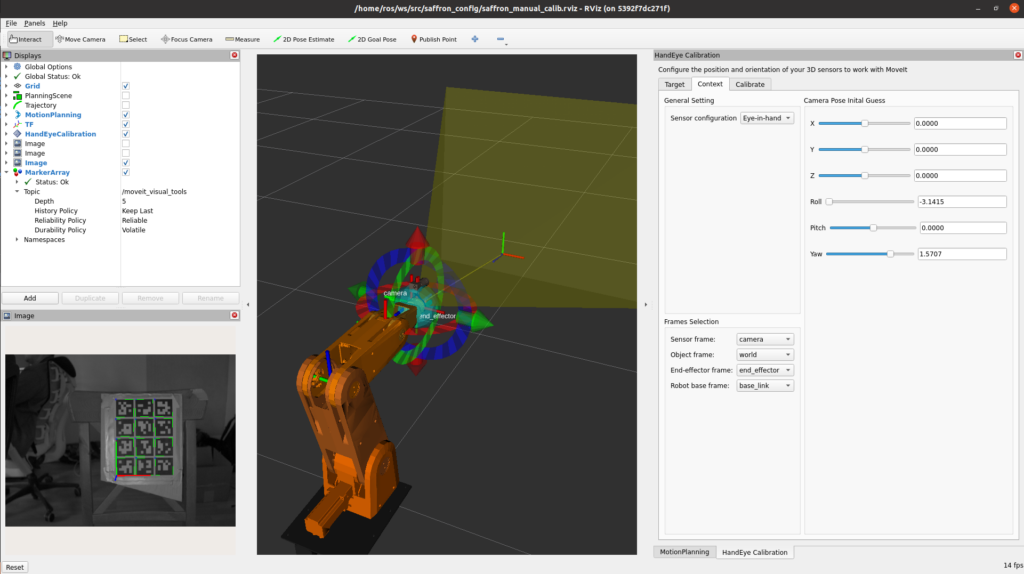

One part of our automation solution is a robotic arm equipped with cameras to capture digital images of the saffron flowers that we use to create complete 3D-models using Neural Radiance Field (NeRF) AI-algorithm. The robot is excellent for a number of delicate tasks and can with the help of computer vision find problems like mold or other damages, as well as sort the product according to quality requirements.