In collaboration with Scania, we are pushing the boundaries of last-mile delivery with “Carrie,” an innovative robot that redefines urban logistics for greater efficiency and sustainability. Carrie is built to integrate seamlessly with Scania’s electric trucks, bridging the final steps of the delivery process autonomously within complex urban environments. This project is part of the HITS 2 initiative (Sustainable and Integrated Urban Transport System), emphasising our commitment to developing robotics for a cleaner, safer urban future.

Carrie’s development addresses the challenges of last-mile delivery, where drivers traditionally spend significant time unloading and transporting goods manually. Designed to reduce both time and physical strain for drivers, Carrie autonomously navigates from truck loading bays to final destinations within large, multi-layered spaces such as shopping malls. Testing at Stockholm’s Westfield Mall of Scandinavia, a major urban retail hub, provides an ideal setting, allowing Carrie to navigate through multi-level corridors, tight turns, and obstacles, showcasing its adaptability in real-world conditions.

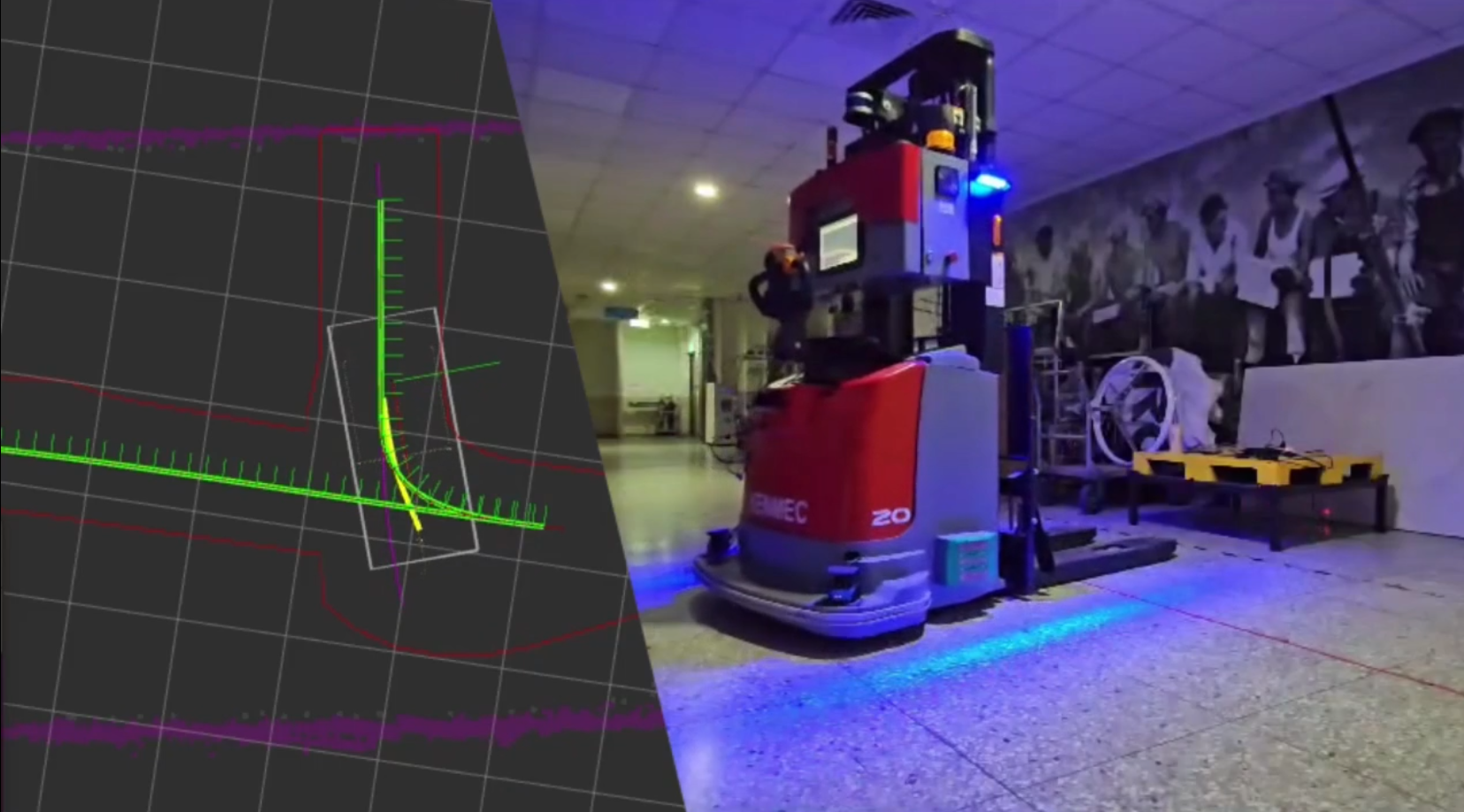

Carrie is equipped with RFID technology to autonomously identify and deliver specific goods cages, ensuring precise placement at designated destinations. Moving at half a meter per second, it achieves a careful balance between efficiency and safety, making it suitable for indoor pathways. Despite its compact design, Carrie can handle standard goods cages with ease, maximising delivery capacity within confined spaces.

A standout feature of Carrie is its ability to autonomously operate the elevator. Through integration with an API of the elevator on site, Carrie can connect to the elevator system, summon the lift, and travel between floors completely on its own. This elevates the robot’s capabilities, making it suitable for multi-story environments and drastically expanding the range of scenarios it can serve.

Carrie uses omniwheels to navigate effectively. These wheels, with their multi-directional rollers, give Carrie smooth and agile movement in all directions, allowing it to easily adjust course or rotate in place as it moves from truck to final delivery location. Omniwheels are crucial to Carrie’s design, as they enable the robot to handle intricate indoor paths with high precision and flexibility, making it ideal for complex delivery routes within large facilities.

Carrie marks a critical step in Scania’s broader vision of integrating autonomous technology into logistics. Beyond 2030, Scania envisions a world where robots like Carrie accompany autonomous, driverless trucks, capable of managing deliveries independently without human intervention. This vision pushes urban delivery towards a new era where robotic and autonomous solutions coalesce to create cleaner, smarter, and more efficient logistics systems. We are proud to be a part of this journey toward the future of urban deliveries.