We worked together with TraktorArvid to develop the intelligent control system for Drever120, an autonomous tractor built for precision farming. The goal is to give farmers a reliable partner in the field, one that can plan, navigate, and work independently while still allowing the farmer to stay in full control.

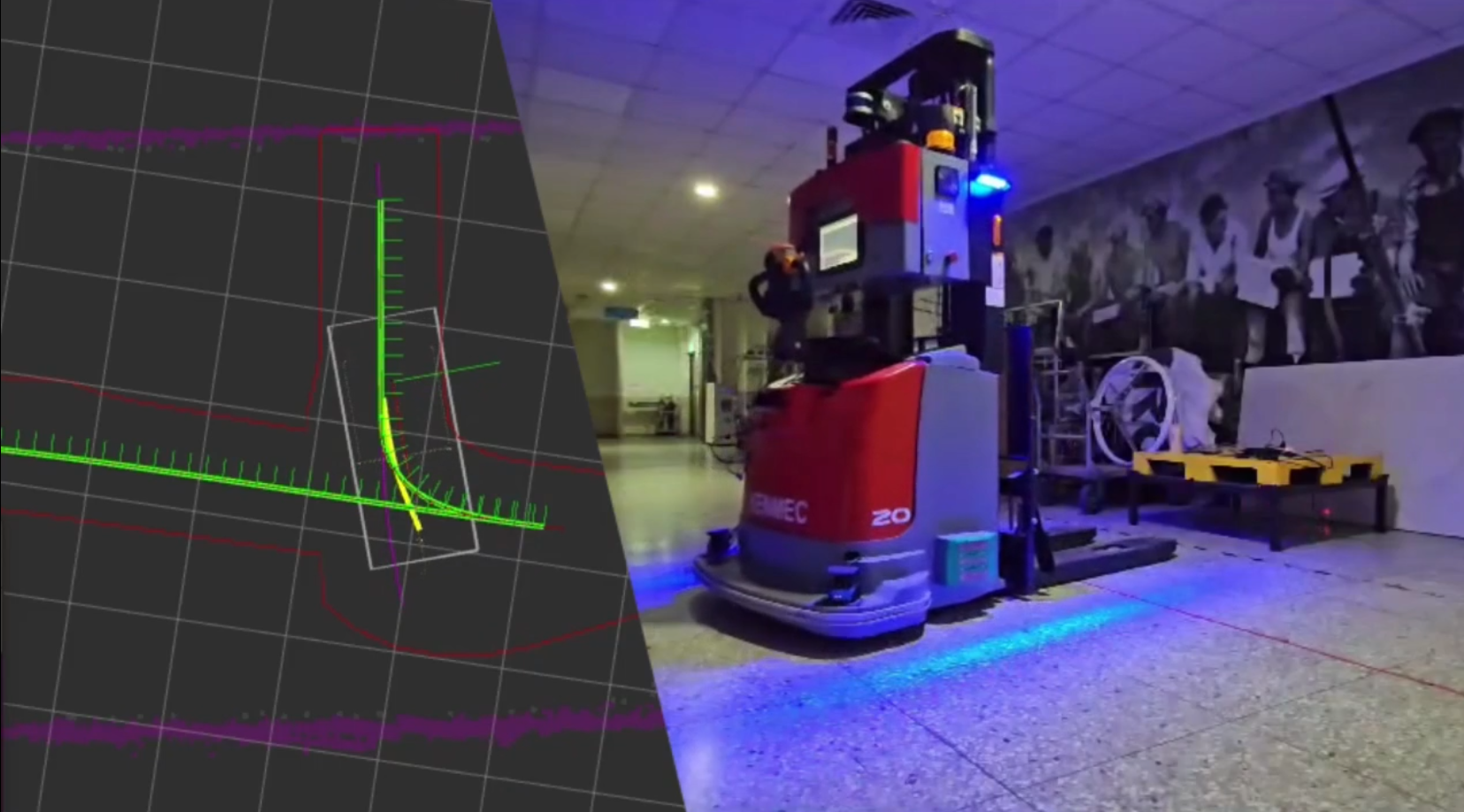

The project began with the creation of a realistic 3D simulator. To make the virtual test environment as close to reality as possible, we scanned an actual field with a drone and recreated it in detail. The simulator works much like a computer game: we send steering commands to the virtual tractor’s wheels, which interact with the simulated ground and respond just like the real machine would. Sensors such as IMUs, GPS antennas, LiDAR, and cameras can be mounted on the simulated tractor, allowing us to test and refine the control system before the physical machine ever turns a wheel.

Behind this work lies a carefully designed mathematical model of the tractor’s motion. This model allows us to combine data from GPS, IMU, and wheel encoders to precisely estimate the tractor’s position using a Kalman filter. It also enables model predictive control, a method where the tractor continuously calculates the best steering and speed commands for the next twelve seconds, choosing the ones that minimize any deviation from the planned route. With this approach, we can even predict how the implement attached behind the tractor will move, ensuring accurate field work without needing sensors directly on the hitch.

Field planning begins with driving a lap around the field’s edge using a remote control, recording the outer boundary. This boundary, or geofence, is saved in a database and used both as a safety feature and as the starting point for generating work plans. Based on this recorded edge, the system automatically calculates optimal routes, including headlands along the outer perimeter and straight passes through the center, even on fields with obstacles that need to be avoided.

To make the system easy to use, we built a web-based interface where farmers can see their Drever120, their fields, tools, and planned jobs at a glance. From the same interface, they can create new tasks, such as harrowing a particular field, and monitor the tractor’s progress in real time through low-latency video streams from the onboard cameras.

Safety is a central part. The system combines the geofence with sensors such as GPS, LiDAR, and safety bumpers to ensure that the tractor stops if something unexpected appears in its path, protecting people, animals, and equipment.

Together with the team at TraktorArvid, we have built not just a simulator but a complete solution: autonomous navigation and planning, a user-friendly control interface, and a robust safety system. Together, these elements bring Drever120 closer to becoming a dependable, autonomous work partner that can save farmers time, improve efficiency, and make farm work less physically demanding.