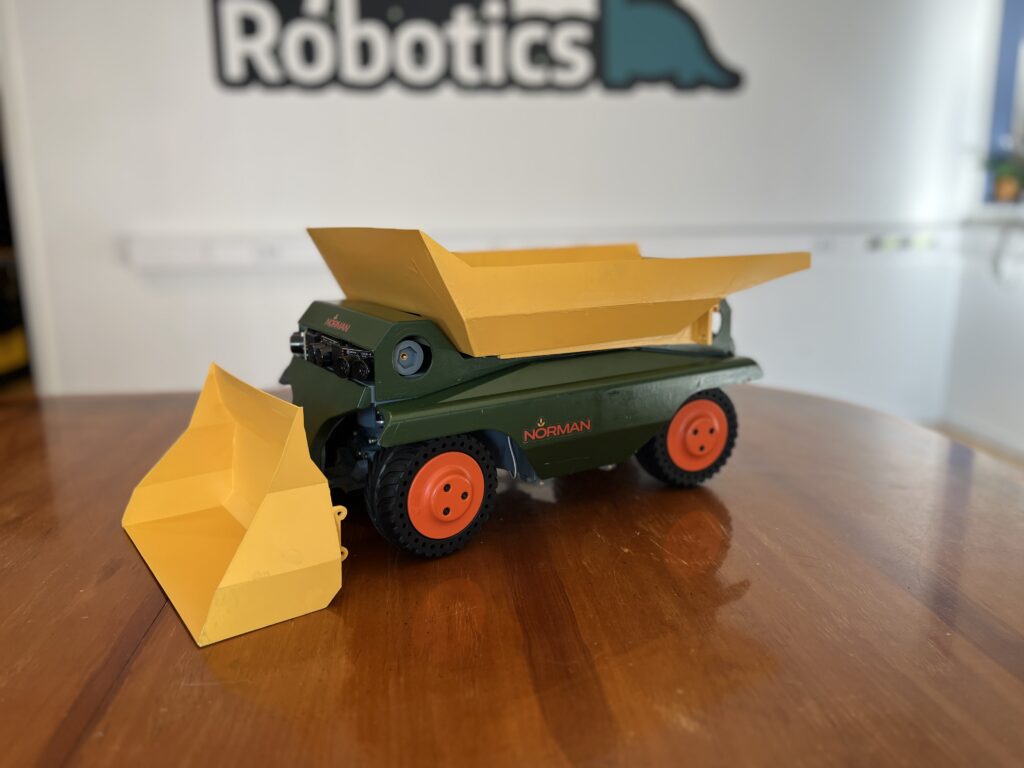

We are developing Norman, an autonomous vehicle designed to make farm work easier and less physically demanding. Norman’s job is to take care of the repetitive and heavy transport tasks around the farm, allowing farmers to focus on caring for animals, harvesting crops, and managing the work that truly matters.

The development of Norman started with a small-scale prototype. This first version allowed us to quickly experiment with sensors, test the follow-me function, and refine the basic driving behavior. Once the concept was proven, we moved on to building a full-sized Norman, capable of handling real farm loads. Today, the robot is undergoing field trials where we collect feedback from farmers and fine-tune its performance for everyday use.

Norman is built to support several common farm activities. It can transport manure, bedding, and feed by following a farmer around the farm. During harvest, Norman can relieve pickers by carrying fruit, berries, or vegetables either in open fields or greenhouses. It can also transport materials needed for fence building and easily move calf hutches from one location to another.

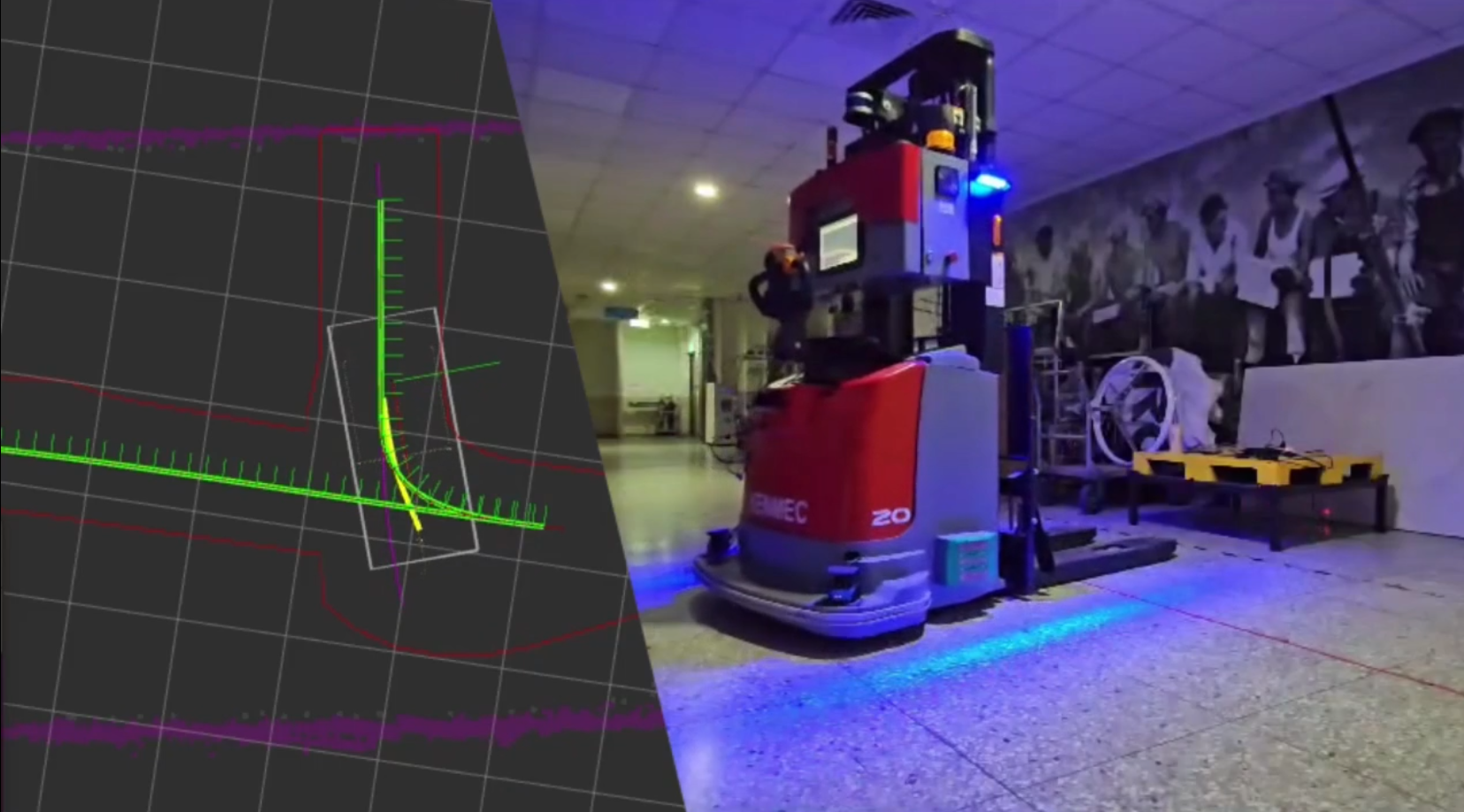

To handle these tasks, Norman operates in two intelligent modes. In follow-me mode, it drives at walking speed behind the operator, keeping a safe distance of two to four meters, and automatically stops if the person gets too close or too far away. In waypoint mode, the operator drives Norman manually along a route once using a remote control. Norman then remembers the path and can repeat it completely on its own, driving back and forth, unloading material at the destination, and returning for the next load, much like a train running on invisible tracks.

Safety and reliability are at the core of Norman’s design. The robot uses a combination of sensors to see and understand its surroundings: a camera for indoor and outdoor localization, ultrasonic sensors to detect obstacles in any direction, a bumper that reacts to collisions, and an IMU sensor that stops the robot if it tilts too much. The operator wears a UWB tag, allowing Norman to know exactly who to follow. If any sensor gets dirty, Norman alerts the user to clean it, ensuring dependable performance. And with a maximum speed of just 5 km/h, Norman moves slowly enough to be safe while still efficient for farm work.

By combining robust hardware, smart software, and careful safety design, Norman is shaping up to become a reliable extra set of hands on the farm. One that tirelessly carries loads, follows the farmer’s lead, and makes daily work just a little bit easier.

The project is funded by the EU and the Swedish Board of Agriculture (Jordbruksverket).

Several partners are collaborating in the development of Norman:

- FLIVAB – Project initiator and idea owner

- QRTech – Embedded programming and electronics

- Agroväst – Project administration

- Bala Agri – Chassis assembly and welding

- Linköping University (LiU) – User study and research

- Dyno Robotics – Autonomy and sensor systems